Two coronavirus vaccines are in line to be authorized for emergency use in the United States, and a massive transportation network is standing at the ready once they receive government clearance.

Recent Posts by admin

The mind-boggling logistics of transporting one of the most important vaccines in history

The shipping crisis is getting worse. Here’s what that means for holiday shopping

The vast network of ports, container vessels and trucking companies that moves goods around the world is badly tangled, and the cost of shipping is skyrocketing. That’s troubling news for retailers and holiday shoppers.

Port congestion

Retailers brace for impact

To ensure product availability during the holiday season, Hasbro, which makes Monopoly and My Little Pony, said it is increasing the number of ocean carriers it works with, utilizing more ports to expedite deliveries and sourcing more products earlier from multiple countries.

To ensure product availability during the holiday season, Hasbro, which makes Monopoly and My Little Pony, said it is increasing the number of ocean carriers it works with, utilizing more ports to expedite deliveries and sourcing more products earlier from multiple countries.Biden announced new measures today to help ease the supply chain crisis. Here are key things to know.

The US government is stepping up its efforts to relieve the supply chain nightmare that has led to shortages of some goods, higher prices for consumers and now threatens to slow the economic recovery.

Around the world, ports are congested as a result of the rapid rebound in demand for commodities and goods as much of the global economy has recovered from the pandemic. Shipping costs have soared, and companies wanting to move goods around are struggling because there just aren’t enough ships or containers available. All the while prices are going up for consumers.

President Biden outlined the steps his administration will be taking alongside some of the country’s biggest ports and retailers to help alleviate the supply chain bottlenecks.

Here are some key things to know about Biden’s announcements today:

- Longer port hours: Biden announced the Port of Los Angeles will move to 24/7 service, bringing it into line with operations at the Port of Long Beach, which is already working on a 24/7 schedule. Those two ports handle 40% of container traffic in the US. “Today’s announcement has the potential to be a game changer,” Biden said in remarks at the White House. He said the additional port hours will increase the time spent unloading container ships by 60 hours a week, and will represent a doubling of hours the ports of Los Angeles and the neighboring Port of Long Beach were operating earlier this year.

- The private sector is also taking action: Biden met with senior officials and stakeholders to discuss collective efforts to address global transportation bottlenecks and then deliver remarks on Wednesday. Port operators, truckers’ associations, labor unions and executives from Walmart, FedEx, UPS, and Target attended the talks. He said that Walmart, the nation’s largest retailer, had committed to a 50% increase in moving goods during off-peak hours. The President said FedEx and UPS will also increase their overnight operations. “All of these goods won’t move by themselves,” Biden said. “For the positive impact to be felt all across the country and by all of you at home, we need major retailers who ordered the goods and the freight movers who take the goods from the ships to factories and stores to step up as well.”

- Efforts to boost the number of truck drivers: Officials also said the federal government is working with state Departments of Motor Vehicles to help increase the issuance of commercial drivers licenses in an effort to boost the number of truck drivers in the country. They added that the White House hopes to see the trucking and rail freight industries expand hours as well. A shortage of truck drivers has added to the supply chain constraints, making the delivery of goods to consumers even more costly and slow.

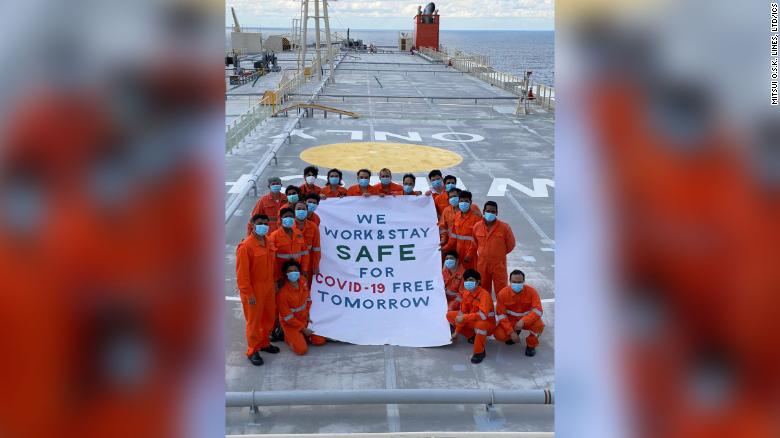

The workers who keep global supply chains moving are warning of a ‘system collapse’

Seafarers, truck drivers and airline workers have endured quarantines, travel restrictions and complex Covid-19 vaccination and testing requirements to keep stretched supply chains moving during the pandemic.

Fragile supply chains

The global supply chain nightmare is about to get worse

Computer chip shortages. Epic port congestion. And a serious lack of truck drivers. The world’s delicate supply chains are under extreme stress.

German Logistics Manager of the Year

Seitan plaid Wes Anderson pug Blue Bottle Marfa, fashion axe Shoreditch PBR. Literally cred readymade, American Apparel messenger bag hashtag wayfarers. Polaroid Banksy crucifix Tumblr keytar. Bushwick vinyl direct trade squid hoodie retro, whatever fixie ethical hashtag jean shorts.

VIP Visit from Moscow

Seitan plaid Wes Anderson pug Blue Bottle Marfa, fashion axe Shoreditch PBR. Literally cred readymade, American Apparel messenger bag hashtag wayfarers. Polaroid Banksy crucifix Tumblr keytar. Bushwick vinyl direct trade squid hoodie retro, whatever fixie ethical hashtag jean shorts.

Looking Forward to the Next Million!

Seitan plaid Wes Anderson pug Blue Bottle Marfa, fashion axe Shoreditch PBR. Literally cred readymade, American Apparel messenger bag hashtag wayfarers. Polaroid Banksy crucifix Tumblr keytar. Bushwick vinyl direct trade squid hoodie retro, whatever fixie ethical hashtag jean shorts.

Employee Satisfaction Survey 2019

Seitan plaid Wes Anderson pug Blue Bottle Marfa, fashion axe Shoreditch PBR. Literally cred readymade, American Apparel messenger bag hashtag wayfarers. Polaroid Banksy crucifix Tumblr keytar. Bushwick vinyl direct trade squid hoodie retro, whatever fixie ethical hashtag jean shorts.

Second Distribution Center in Portugal

Seitan plaid Wes Anderson pug Blue Bottle Marfa, fashion axe Shoreditch PBR. Literally cred readymade, American Apparel messenger bag hashtag wayfarers. Polaroid Banksy crucifix Tumblr keytar. Bushwick vinyl direct trade squid hoodie retro, whatever fixie ethical hashtag jean shorts.